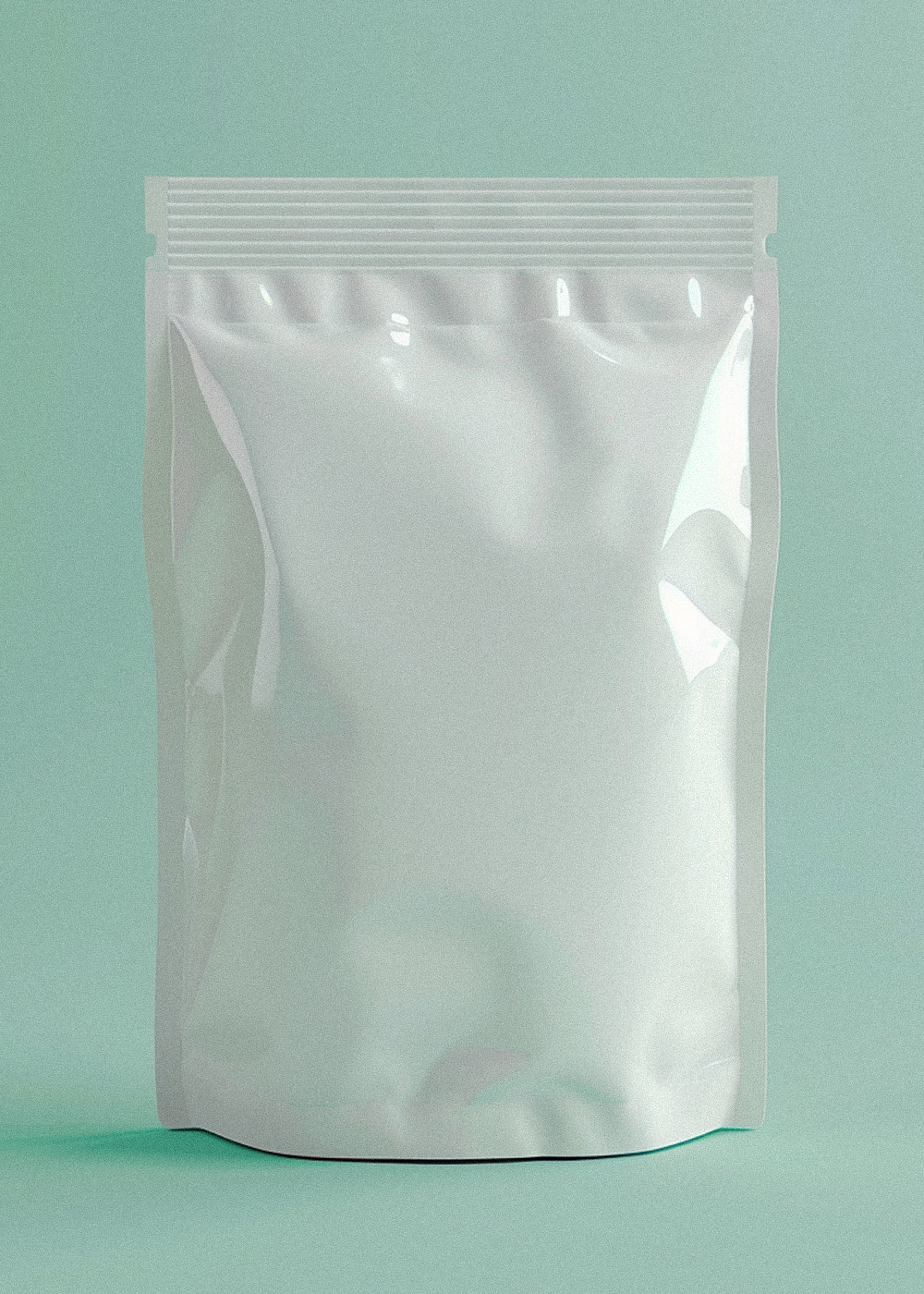

General Description

Flexible packaging demands materials that are lightweight, durable, and visually striking. Our masterbatches meet these needs with superior color, protection, and processing performance. From food films to industrial and retail packaging, we help brands enhance quality, efficiency, and shelf appeal.

PRODUCTION METHODS SUPPORTED

Our masterbatches are optimized for all major flexible packaging production technologies:

1

BLOWN FILM EXTRUSION

Ideal for grocery bags and industrial liners.

2

CAST FILM EXTRUSION

Used for high-clarity packaging films and laminates.

3

BOPP FILM PRODUCTION

Tailored masterbatches for high-speed orientation lines, offering excellent dispersion, thermal stability, and compatibility with coextrusion and surface treatments.

4

LAMINATION AND COEXTRUSION

For multi-layer barrier films and functional packaging.

5

PRINTING AND CONVERSION

Compatible with downstream processes like flexographic and gravure printing.

Each formulation is designed to ensure excellent processability, minimal waste, and consistent performance across production runs.

BENEFITS FOR THE FLEXIBLE PACKAGING INDUSTRY

1

ENHANCED VISUAL APPEAL

Vibrant colors, smooth finishes and high opacity for shelf impact.

2

IMPROVED FUNCTIONALITY

Additives that enhance film properties.

3

REGULATORY COMPLIANCE

Food-contact approved grades available for sensitive applications.

4

CUSTOMIZATION AND FLEXIBILITY

Tailored solutions for mono- and multi-layer film structures.

5

SUSTAINABILITY OPTIONS

Compostable masterbatches available for bio-based films.

From clarity to color, our masterbatches empower flexible packaging with performance, protection and visual impact.

Request a Quote