Description

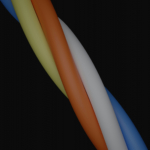

We specialize in color masterbatches, offering a vast palette of standard and custom shades. Our expert colorists, supported by computerized colorimetry tools and a comprehensive color archive, deliver precise color matching tailored to your brand or technical requirements. In-house fiber spinning lines and a nonwoven pilot lab line allow us to simulate real production conditions and validate performance before scale-up.

Technical Information

End Products

Technical Information

Contact us

Request a Quote

1

Polymer Compatibility

PP and PET fiber-grade resins.

2

Carrier Resins

PP or PET or PBT based, matched to the base polymer.

3

Masterbatch Types

- COLOR MASTERBATCHES

Standard and custom shades of high performance. - BLACK MASTERBATCHES

High jetness grades with excellent thermal resistance. - WHITE MASTERBATCHES

High TiO₂ content and increased thermal stability to provide excellent performance in the end application. - ADDITIVES

UV stabilizers, softeners, hydrophobic agents, antioxidants, antimicrobials, flame retardants.

4

Form

Granules for precise dosing and uniform dispersion.

5

Processing Methods

Suitable for melt spinning, BCF, CF, POY, FDY, staple fiber extrusion, spunbond and meltblown.

End Products

Our masterbatches are used in a wide range of fiber-based applications, including:

Contact us

Request a Quote

1

Carpet Yarns (BCF)

2

Textile Filaments (CF, POY, FDY)

3

Staple Fibers for Spun Yarns and Nonwovens

4

Hygiene fF

Diapers, wipes and sanitary products.

5

Medical Textiles

Masks, gowns and filtration media.

6

Home Textiles

Upholstery, curtains and mattress components.

7

Industrial Fibers

Automotive linings, insulation and packaging fabrics.

From color precision to fiber performance—our masterbatches for PP and PET fibers deliver unmatched consistency, functionality and production-ready reliability.

Contact Us